Industrial Air Purification Systems vs. General Ventilation: Key Differences

Maintaining clean air in industrial environments is a critical concern for manufacturers, fabricators, and processing facilities. Airborne contaminants such as welding fumes, fine dust, oil mist, and chemical vapors can pose serious risks to worker health, equipment performance, and regulatory compliance. When addressing these challenges, many facilities consider two primary approaches: general ventilation and industrial air purification systems. While both aim to improve indoor air quality, they function very differently and offer distinct advantages and limitations.

Understanding the key differences between industrial air purification and general ventilation is essential for selecting the right solution for a given application.

What Is General Ventilation?

General ventilation, sometimes referred to as dilution ventilation, involves introducing fresh air into a workspace while exhausting contaminated air out of the building. This approach relies on air movement to dilute airborne pollutants, reducing their concentration to acceptable levels.

Common examples of general ventilation include:

- Roof-mounted exhaust fans

- Make-up air units

- Open doors, windows, or louvers

- HVAC systems designed primarily for temperature control

General ventilation is often used in facilities where contaminants are relatively low in concentration or not generated at a specific source. It can be effective for controlling heat, odors, and overall air circulation in large spaces.

However, general ventilation does not remove contaminants at their point of origin. Instead, it allows pollutants to disperse throughout the workspace before being exhausted, which can expose workers and equipment to harmful particles for extended periods.

What Is Industrial Air Purification?

Industrial air purification systems are designed to capture, filter, and remove airborne contaminants directly from the air inside a facility. These systems typically use advanced filtration technologies—such as cartridge filters, HEPA filters, or electrostatic precipitators—to physically remove pollutants rather than simply diluting them.

Industrial air purification can be configured in several ways:

- Source-capture systems, which collect contaminants directly at the point of generation (such as welding stations or cutting tables)

- Ambient air purification systems, which continuously clean the air within a defined area

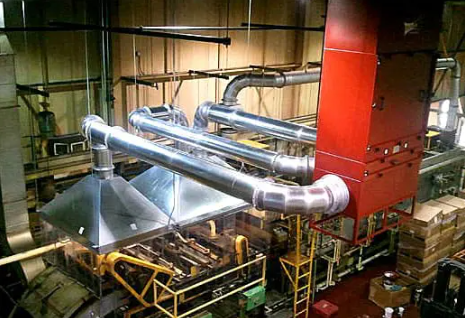

- Centralized systems, which serve multiple processes through ductwork

- Standalone or modular units, which offer flexibility for changing layouts

Unlike general ventilation, industrial air purification systems are engineered specifically to address industrial contaminants like welding fumes, combustible dust, oil mist, and fine particulate matter.

Key Differences Between Industrial Air Purification and General Ventilation

- Contaminant Control Effectiveness

General ventilation reduces airborne contaminants by dilution, which may not be sufficient for processes that generate high concentrations of hazardous particles. Industrial air purification physically removes contaminants from the air, making it significantly more effective for controlling fine particulates and toxic fumes.

- Source Capture vs. Dilution

Industrial air purification systems can capture pollutants at or near their source, preventing them from spreading throughout the facility. General ventilation allows contaminants to disperse before removal, increasing overall exposure.

- Energy Efficiency

Ventilation systems often require large volumes of conditioned air to be exhausted and replaced, which can increase heating and cooling costs. Industrial air purification systems typically recirculate filtered air back into the facility, helping reduce energy consumption while maintaining air quality.

- Regulatory Compliance

Many occupational health and safety regulations focus on controlling exposure to specific airborne contaminants. Industrial air purification systems are often better suited to meet OSHA, EPA, and local air quality requirements, especially in processes involving welding fumes, dust, or mist.

- Impact on Equipment and Cleanliness

Airborne contaminants can settle on machinery, leading to increased maintenance, reduced accuracy, and premature equipment failure. Industrial air purification helps maintain cleaner environments, while general ventilation does little to prevent particulate buildup.

When General Ventilation May Be Enough

General ventilation can be appropriate in environments where:

- Contaminant levels are low and non-toxic

- Heat and humidity control are the primary concerns

- Processes do not generate localized airborne hazards

In these cases, ventilation may serve as a baseline air movement strategy, but it is rarely sufficient on its own for industrial contaminant control.

Why Industrial Air Purification Is Often Necessary

For facilities engaged in welding, metal fabrication, machining, or manufacturing processes that generate airborne pollutants, industrial air purification is typically a more reliable and effective solution. By directly removing contaminants, these systems help protect worker health, support compliance, and improve overall operational efficiency.

In many modern facilities, industrial air purification and general ventilation are used together—ventilation to manage temperature and airflow, and air purification to control hazardous contaminants.

Conclusion

While general ventilation plays an important role in maintaining airflow and comfort, it is not a substitute for industrial air purification in environments where airborne contaminants pose a risk. Industrial air purification systems offer targeted, efficient, and compliant solutions for removing harmful particles from the air, making them a critical component of a comprehensive indoor air quality strategy.

Understanding the differences between these two approaches allows facility managers and engineers to make informed decisions that support safety, productivity, and long-term operational success.